This document defines the methods to be used to ensure that the electrical works to be conducted at a project site are in compliance with the approved designs and approved materials.

The method of statement covers the procedure for Material Delivery Inspection, Installation and Inspection of PVC conduit embedded in wall, false ceiling or slab.

This document applies to the inward site inspection, installation and inspection methods to be adopted for the PVC electrical conduit installation work on a building project.

The Project Manager is the overall responsible person for the process of implementation of the works.

Construction Manager/Site Engineer will be responsible for all electrical construction activities at the site and will directly supervise through supervisor/skilled workmen at the work site.

Site Engineer will be responsible for arranging and controlling the inspection and testing activities.

Furthermore, it is the responsibility of each individual employed in the project to take due care to ensure their own personal safety and that of their work colleagues.

Tools and Equipment

- PPE for all staff and labor

- Measuring tape and setting out markers

- Electric hand grinder

- Bending springs

- Hack saw cutter

- Fitters tool box

- Electricians tool box

- Certified mobile scaffolds / step ladder

Requirement Prior to Start of PVC Conduit Installation Work

The raceway system material such as PVC conduit should be according to the site requirement and in accordance with the approved/design drawing.

It should be noted that the materials used in this work area are of valuable nature and that they shall be stores in a secure location, and access to these materials shall be strictly controlled.

All materials delivered to the site will be first to be inspected by the store in-charge I site in-charge.

All materials should be check in accordance with the site requirement, approved design and material qualification.

It must also be free from any damage caused during the delivery to site.

Delivery documentation shall be checked for completeness.

Defective or damage materials shall either be returned to the supplier’s facility or stored on site at a suitable quarantine location.

The site engineer has the authority to perform any inspection for the material from his own point of view.

Preparation of Works

Before the start of the work installation, the following are required first to be done accordingly.

Check if the design of the raceway system (PVC conduit) shop drawing is approved.

Check if the design in accordance with the project specification.

Check if there is an available site access in the work area of installation. The work area should be clean, safe and the temporary services had been provided.

Check if the raceway system (PVC conduit installation) material have been ordered and inspected at the supplier’s facility and ready to be delivered at site.

Delivery and inspection of PVC conduit Materials

All delivered material shall be inspected upon arrival at site.

Delivered material shall be in accordance with the approved design and approved shop drawing.

Material should have no defect or or damage when delivered on site.

Delivered material that does not conform to the approved submittal and does not conform on the mentioned above shall be returned to the point of supply or stored on the site at a suitable quarantine store.

An NCR shall be raised for such non-conformance of the material delivery.

Setting out of Work

Prior the start of the delivery of the raceway materials, setting out of work shall be done to determine the location of any equipment.

The setting out of conduit installation work must be based on the approved installation / shop drawing.

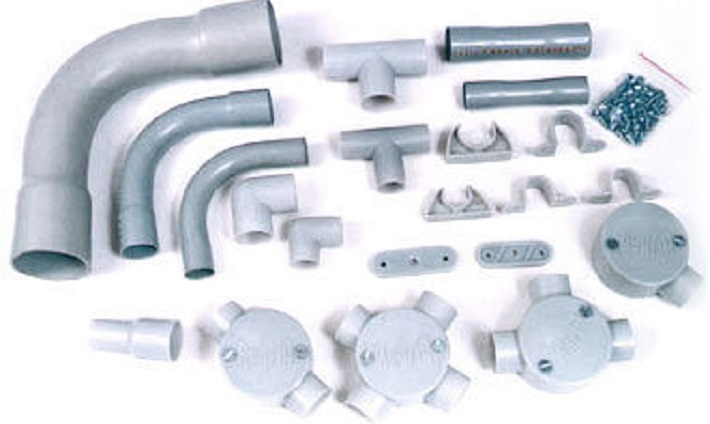

Installation of PVC Electrical Conduit and Accessories

Surface Conduit Installation

Mark the conduit routing. The marking shall be in accordance with the approved shop drawing.

Check the routing of the location of the services as per coordinated drawing.

Make a hole by using electric drill machine on the structure.

Insert fastener, fix the base support and conduit.

Fix the top piece of saddle to hold the conduit.

Tight all nuts by using machine screw.

PVC Conduit Installation in Slab

Mark the conduit routing and position of the junction box as per site condition (after shuttering and preliminary reinforcement) in accordance with the approved shop drawing.

The location of the junction box, pull boxes and other accessories shall be in accordance with the approved shop drawing.

Install the approved material as per mark layout.

Seal the holes with plugs to avoid entering of mortar in the containment system.

The laying of conduit shall be done in coordination with the bar binder.

After removal of shuttering, clean the conduit and pull the bar binder.

Install the conduit in chase or on surface as required / approved.

Inspection and Testing of PVC Conduit Installation Work

Upon completion of the first raceway installation, inspection shall be done.

Notice of inspection shall be advised to Consultant for their discretionary attendance and witnessing.

Inspection notice shall be advised at least 24 hours prior to date and time of inspection.

The installation shall be inspected in accordance and compliance with the electrical design requirements.

Health & Safety Requirements

Proper safety harness to be used and secured, if required.

All personal protective equipment shall be used as appropriate according to the nature of the job.

Housekeeping at workplace shall be of good standard and all cut pipes and debris shall be removed.

Inspection Checklist for PVC Conduit Installation

Check all the conduit if it is as per approved material submittal.

Make sure the shop drawing is approved.

No physical damage for conduit.

Check if there is a cover at the end of the conduit.

All covers of junction boxes are securely tight.

Joint of the conduit is properly done.

The size of the conduit installed is in accordance with the approved shop drawing.

Conduit is installed as per approved shop drawing.