Circuit Breaker is one of the most important equipment in the power distribution system. This is because of the function of the equipment itself which is, the ability to open a circuit or to break the circuit during maintenance work or when there is fault in the system without getting damaged.

Circuit breaker is a device that is capable of making and breaking an electric circuit under normal and abnormal condition. The function of a circuit breaker is just like a water tap that stops and allows a water to flow through it.

Types of Circuit Breaker

Circuit breakers may be classified into 7 types such as the following:

- Bulk Oil circuit breakers

- Minimum Oil Circuit Breakers

- Vacuum Circuit Breakers

- Gas Insulated Circuit Beakers

- Air Insulated Circuit Breakers

- Miniature Circuit Breakers

- Moulded Case Circuit Breakers

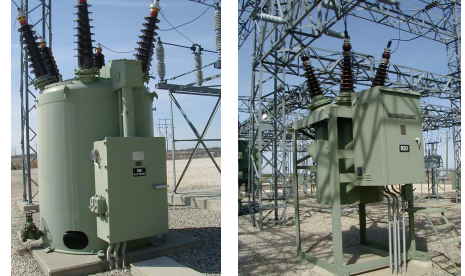

Bulk Oil Circuit Breakers

Bulk oil circuit breakers are already obsolete as they are very bulky and expensive to maintain. It is also a high fire hazard. It is mainly used at distribution voltage levels as the operating speed is rather slow.

In this breaker the main contacts are immersed in oil which has the dual function of quenching the arc of the current as well as n insulating medium.

During contact opening to interrupt the current, the arc produced causes dissociation of the oil into hydrogen and carbon.

The hydrogen helps to extinguish the arc while the carbon causes deterioration of insulation level of the oil. As carbon is a conductor the oil has to be replaced after several fault clearances.

Minimum Oil Circuit Breaker

Minimum Oil circuit breakers are generally similar in construction as the bulk oil circuit breakers except that the latter contain less oil.

Minimum oil c circuit breakers are becoming less popular due to high fire risks but still widely used in

outdoor transmission substations. Their operating time is much faster than bulk oil circuit breakers.

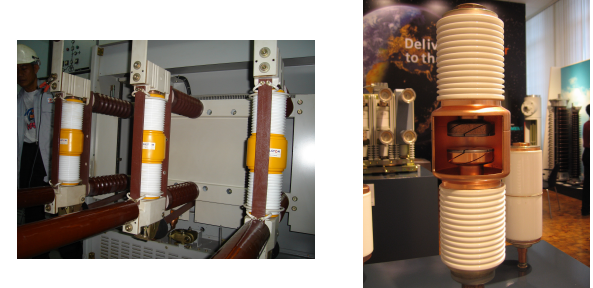

Vacuum Circuit Breakers

Vacuum circuit breakers are more popular at distribution voltage level. They require minimum maintenance except to replace the vacuum bottle if a leak has occurred.

These types of breakers are getting more popular in recent years and tend to replace the oil type. The reasons being they have no fire risk and have high reliability with long maintenance free period.

For these breakers the main contacts are housed within a vacuum in an insulating cylinder of glass or ceramic having metal end plates supporting the contacts. The vacuum device is usually referred to as a vacuum interrupter.

At 11kV normally only one vacuum interrupter per phase is used. But at 33kV two interrupters may be used in series per phase.

The closing mechanism for VCBs is usually of the solenoid or spring-closing type. Contact wear is very low

because the arc takes place in vacuum.

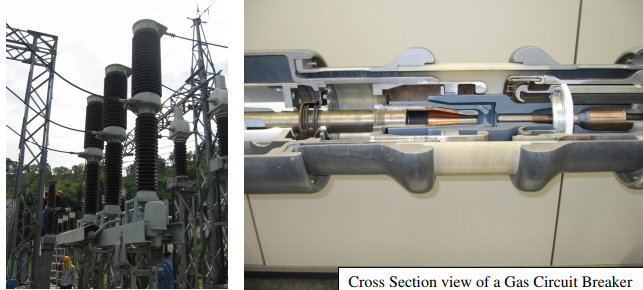

Gas Insulated Circuit Breakers

The most commonly used circuit breakers nowadays are the gas circuit breakers especially at transmission level. Gas circuit breakers normally using sulphur hexafluoride (SF6) gas as the insulating medium require little maintenance and have very fast operating time.

Well design gas circuit breakers may last more than 25 years without much maintenance. The interrupter unit and the contacts are housed in as Sf6 filled chamber.

The interrupter serves as a nozzle for the SF6 gas to pass through it at high speed across the arc during contact opening and thus rapidly quenches the arc. SF6 gas has a high recovery rate and minimal residue.

The closing and tripping mechanisms are similar to those of other breakers.

Air Insulated Circuit Breakers

Air insulated circuit breakers (ACBs) are normally used at distribution voltage levels of 3.3kV and below especially in power stations as they are often modular in design and may conveniently be arranged into multi-tier switchboards.

They also pose minimum fire hazard as there are no combustible materials used. The operating principle of this air circuit breaker is that the arc of the current is directed into a chute where the arc resistance becomes higher and the arc rapidly diminished to zero.

The forces directing the arc into the chutes of the ACBs are the electromagnetic and thermal forces of the arc itself. In certain cases, to assist in the quenching of low current arcs, an air cylinder is fitted to each pole to direct a puff of air across the contact faces as the breaker opens.

This helps to reduce erosion of the contact surfaces. Operating mechanisms for ACBs are similar to those used in OCBs.

Miniature Circuit Breakers

MCBs are the smaller both in physical size and particularly the ratings compared to MCCBs. Normally it is of a single pole design. It is small, manually closed and electrically or manually opened.

The MCBs have built-in bimetal strip to trip the MCBs when excessive currents pass through them. The operation of the bimetal corresponds to predetermined inverse-time/current characterstics.

But for current above 6 to 8 times rated current MCBs will trip instantaneously actuated by a magnetic over current trip element. Neither part of the overall operation time of the MCBs are adjustable.

Moulded Case Circuit Breakers

Generally MCCBs are similar to MCBs but have the following important differences:

- Current ratings are generally in excess of 100A up to 2.5 kA or higher. Voltage ratings up to 1000 V a.c and 12000 d.c.

- The breakers are larger, in line with the level of ratings. MCCBs are available as single pole, double pole, and triple pole or four pole units. However, for multi-pole units they are moulded in one common housing. Further, the switch for the neutral circuit is a separate device coupled to the multi-pole MCCB.

- The overall operating tie may be adjustable especially the larger ones.

- Since they are of higher ratings MCCBs are normally positioned close to the power source than the MCBs.

Types of Site Electrical Test conducted on a Circuit Breaker

Timing Test: To measure the speed of breaker operation. Usually for opening and closing operation.

Contact Resistance Test: To measure the resistance value of the main contact( fixed contact and moving contact)

Dew Point Test for SF6 Gas on GCB: To measure the moisture contents of the SF6 gas.

Vacuum Test for VCB: To check that there is no leak on the Vacuum Insulation.

Discover more from Electrical Engineering 123

Subscribe to get the latest posts sent to your email.