When doing solar panel installation on roof tops there are structural considerations to be investigated and analyzed. Solar panels can be placed on new or existing buildings.

Solar panels can easily and inexpensively be incorporated at the time of design for new or future construction.

The structural elements will need to accommodate the additional loading from the system self-weight (dead load), snow build-up, and wind uplift etc.

Existing buildings must be investigated due to the additional loading caused by the solar panels. Since many agencies regulating the building codes have modified the base snow load, it must be validated in addition to considering the weight of the solar panels.

All future loading must be considered and all structural elements must be analyzed from the roof deck to the foundation.

The roof has the capacity to support a minimum of 6 pounds per square foot additional dead load for PV system.

So we have to confirm with the building designer and structural engineer as to the building roof structure’s ability to support the additional weight and wind loading of a roof solar system.

Also, review the impact on roofing warrantee of siting panels over roofing.

Different types of solar installation can be used for roof top.

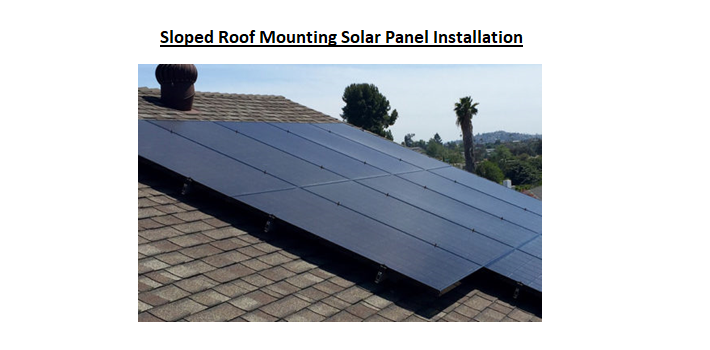

Sloped solar panels on roof mounting systems

When it comes to residential solar installations, solar panels are often found on sloped rooftops.

There are many mounting system options for these angled roofs, with the most common being railed, rail-less and shared rail.

All of these systems require some type of penetration or anchoring into the roof, whether that’s attaching to rafters or directly to the decking.

Ballasted structure

This is a common alternative used on solar installations unable to penetrate either the roof or the ground.

Concrete blocks are placed throughout a project to secure an array to the ground or the roof and prevent wind lift or other movement that can cause damage to the solar panel system.

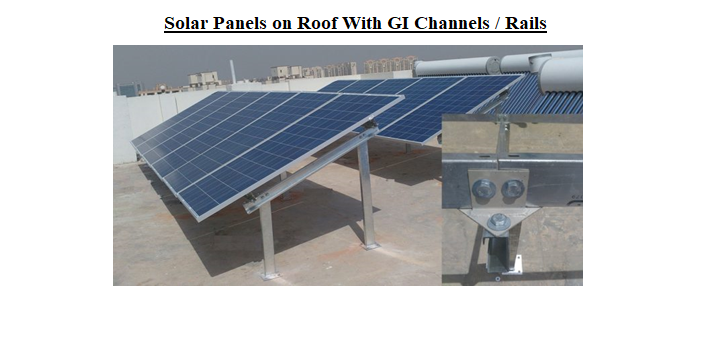

In below image Solar panel mount to the respective roofing is fixed on the roof.

This mount is made of galvanized steel, aluminum or stainless steel.

The rooftop solar panel mount usually consists of two horizontal mounting rails, which are fixed to the roofing with roof anchors.

A roof has to provide just the right conditions for your solar panels to perform well.

Roofing solar panel systems are designed to get any accumulated water off and safely away from the building.

Roofing system should be designed to shed water from the rooftop and away from the building. But, when solar panels are installed without regard for this, racks and wiring often interrupt the flow of water and keep it from draining properly. Water could even be forced upward, which usually results in a leak. Repairing a roof can be much more difficult when there are solar panels installed.

All steel materials should be hot dip galvanized.

Bolts should be properly fixed.

Fixing of panels should be in level.

Solar panels should be cleaned on regular basis for better performance.

Roof Slab Structural Analysis for Solar Panels

Need of visual inspection

- To recognize the types of structural defects

- To identify any signs of material deterioration

- To identify any signs of structural distress and deformation

- To identify any alteration and addition in the structure, misuse which may result in overloading.

Installing arrays of solar panels on an existing roof involves attaching solar panels and their mounting system to the existing building.

The mounts for the solar panel support structure concentrate loads from the panels and associated wind, seismic and snow loads at discrete points on the existing roof structure.

Weight of a ballasted photovoltaic solar system is approximately 4.5 to 6 pounds per square foot.

The actual weight depends on the system’s location on the roof, the tilt of the modules (typically 5 to 20 degrees), and the height above the ground.

Another way to interpret this data is to say that a typical solar installation (i.e. not thin film) will require approximately 0.5 pounds of roof steel per square foot.

Thin film solar weighs quite a bit less, but it’s less efficient; therefore, a much greater quantity is required.

The condition of the roof structure must be assessed before a rooftop solar energy system can be installed.

This assessment should address whether the existing structure has excess capacity for additional loads due to a solar installation or if modifications are necessary for the solar installation.

A prescriptive pathway to expedite permitting for installations that meet requirements relating to:

- Building type, roof structure, and material requirements

- Loading requirements (not to exceed 4.5 pounds per square foot). On average, solar panels and the mounting equipment weigh 2-4 lbs. per square foot (10-20 kg per square meter), which is usually within the acceptable limits of your roof.

- Height restrictions (not to exceed 18 inches above the roof )

- Positive attachment to the roof structure (rather than ballasted systems)

What is the surface area of your solar panels required for your total power demand?

A typical example will be as follows. From the manufacturers catalogue;

The Size of the PV module with a DC rating of 300W (Nom.) = 2080mm (l) X 992 mm (w) X 50 mm (d).

The weight of each panel is given there as 26 kg for the bare module. (This is important because if you intend to install the array on your roof top or on a built up structure, they should be capable of bearing this weight with strength to spare).

Total solar panel requirement?

Assuming your total building load is 4 kW, by a rule of thumb a PV panel area of 34 sq. m is required for your needs.

34/2.08* 0.992 =4 (i.e.17) PV modules as in the example.

And your roof structure or the built up structures should be capable of withstanding the load of;

17*26kg = 442 kg + the support structure weight (minimum).

In addition to this the weight of your maintenance staff, cross winds and any snow in the winter should be included in your structural strength calculations.

Discover more from Electrical Engineering 123

Subscribe to get the latest posts sent to your email.