On this page you can find information about the circuit breaker types or classification by the interrupting medium used i.e. oil, air, vacuum or gas etc.

Oil Circuit Breakers

Oil has an excellent dielectric strength which enables itself not only to be used as an interrupting medium but also as insulation within the live parts.

The interrupting technique of oil circuit-breakers is called “self-extinguishing”, since the oil can produce a high pressure gas when it is exposed to heat resulting from arc.

In other words, arc can be cooled down by the gas produced proportional to arc energy.

During the arc interruption the oil forms a bubble comprising mainly hydrogen.

It is found that arc burning in hydrogen gas can be extinguished faster than other types of gases.

However, hydrogen cannot be used as interrupting medium, as it is not practical to handle.

Oil circuit-breakers can be divided according to methods of arc interruption into bulk oil and minimum oil types:

Bulk oil type

This type of circuit-breaker contains a large amount of oil and requires a large space.

It could cause environmental problems after an explosion. It is therefore limited to the low voltage level.

The main contacts and live parts are immersed in oil which serves as an interrupting medium and insulates the live parts.

Plain-break circuit-breakers are considered as bulk oil type, since the arc is freely interrupted in oil.

The minimum oil type

In the minimum oil type the volume of oil is reduced and used only in an explosion chamber.

The other difference from the bulk oil type is the insulation, which is made of porcelain or solid insulating material.

Single break minimum oil circuit-breakers are used in the voltage levels of 33-132 kV.

When higher ratings are required, the multi-break type is then applied with a combination of resistors and capacitors.

These resistors and capacitors are applied in order to provide uniformity to the voltage distribution.

Air Blast Circuit Breakers

The arc interruption of air-blast circuit-breakers is carried out by introducing the high pressure air flow in axial or cross directions.

In axial type, the arc is cooled down in an axial direction until the ionization is brought down to zero level.

The current is then interrupted at this point. In contrast to the axial type, the cross type will compress the air and blow into an arc-chute compartment.

Performance of air blast circuit breakers depends on many factors, for example, operating pressure, the nozzle diameter and the interrupting current.

The advantages of air-blast circuit breakers

- Cheap interrupting medium

- Chemical stability of air

- Reduction of erosion of contacts from frequent switching operations

- Operation at high speed

- Short arcing time

- Being able to be operated in fire hazard locations

- Reduction of maintenance frequency

- Consistent breaking time

The disadvantages of air-blast circuit-breakers

- high-level noise during the operation and the requirement for the air to remain dried

- Similar to oil circuit-breakers, resistors and capacitors are needed when air-blast circuit-breakers are used in very high voltage levels

- The serious problem which could occur during small current interruption is a chopping current

- the velocity and pressure of air-blast circuit-breakers are independent of interrupted parts

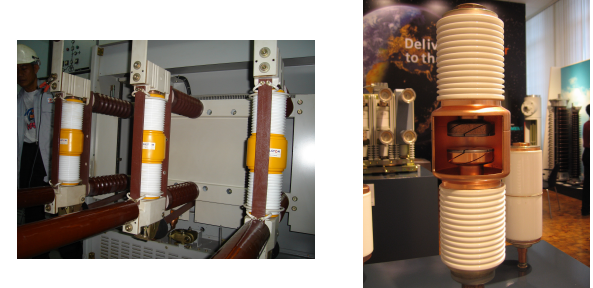

Vacuum Circuit Breakers

The dielectric strength of vacuum is considerably higher than other interrupting mediums.

Hence, a contact separation of around 1 cm is enough to withstand high voltages.

Rate of dielectric recovery of vacuum is much faster than that of air.

The interrupting technique of vacuum circuit-breakers is different from other types of circuit breakers.

Arc extinguishing process is governed by a metal surface phenomenon during their contacts part.

In other words, the arc is not extinguished by an interrupting medium but by the metal vapour.

The vacuum arc can be only cooled down by using a magnetic field which can move the arc over the contact surfaces.

In order to do so, the contacts are manufactured with spiral segments.

This technique can also prevent contact erosion of vacuum circuit breaker.

SF6 Circuit-Breakers

SF6 gas and its characteristics were discovered in 1920s but the development and use of SF6 gas as an interrupting medium for circuit breakers began in 1940s.

However, the SF6 circuit breakers first came to the market in 1960s.

The properties of SF6 gas are superior to other interrupting mediums as follows:

- High dielectric withstand characteristic. For example, SF6 gas at absolute pressure has twice the dielectric strength of air and at 3 bar it is comparable to oil.

- High thermal conductivity and short thermal time constant (1000 times shorter than air) resulting in better arc quenching.

- Arc voltage characteristic is low thus resulting in reduced arc-removal energy.

- At normal conditions, SF6 is inert, non-flammable, non-corrosive, odorless and nontoxic.

SF6 circuit-breakers are predominant in high voltage levels with the high short circuit capability up to 63 kA.

They can be used as dead tank circuit-breakers, live tank circuit-breakers and in gas insulated substation (GIS).

Types of SF6 circuit breakers

Double-pressure SF6 circuit-breakers

This type is developed by using principles similar to air-blast circuit-breakers.

The contacts are located inside the compartment filled with SF6 gas.

During the arc interruption, the arc is cooled down by compressed SF6 from a separate reservoir.

After the interruption, SF6 gas is pumped back into the reservoir.

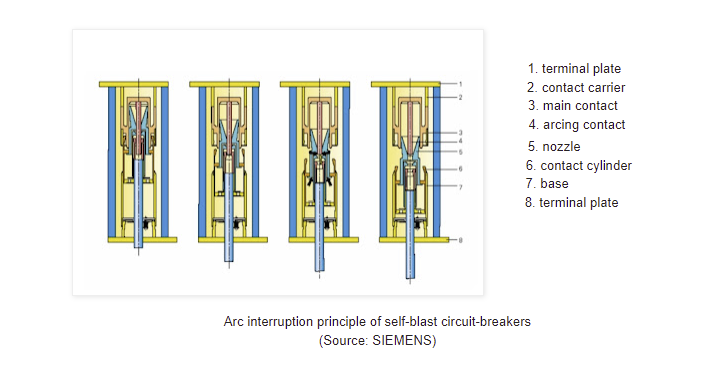

Self-blast SF6 Circuit Breakers

The interrupting chamber of this type of circuit-breaker is divided into two main compartments with the same pressure (around 5 atm).

During the arc interruption, the gas pressure in the arcing zone is heated resulting in high pressure.

This high pressure gas from the other compartment then blasts into the arcing zone and in the meantime cools the arc column.

Finally, the arc is extinguished.

This type of circuit-breaker is normally used in high voltage levels up to 123 kV.

Puffer-type SF6 circuit-breakers

The principle of this type is to generate compressed gas during the opening process.

Moving contacts move the piston and thus compressing the gas in the chamber.

As a result, the compressed gas flows along the arc channel and thereby extinguishing the arc.

Discover more from Electrical Engineering 123

Subscribe to get the latest posts sent to your email.