What is an Electric Motor?

An electric motor is an electromagnetic device that converts electrical energy into mechanical energy by applying the law of electromagnetic induction. The first ever electric motor was invented by William Sturgeon in 1832 which was not promoted as for commercial purposes. First commercially successful electric motor was created in 1873. Today, electric motors can be found in a variety of appliances including industrial fans, blowers, machine tools, house hold appliance etc.

The very basic principal of functioning of an electrical motor lies on the fact that force is experienced in the direction perpendicular to magnetic field and the current, when field and electric current are made to interact with each other.

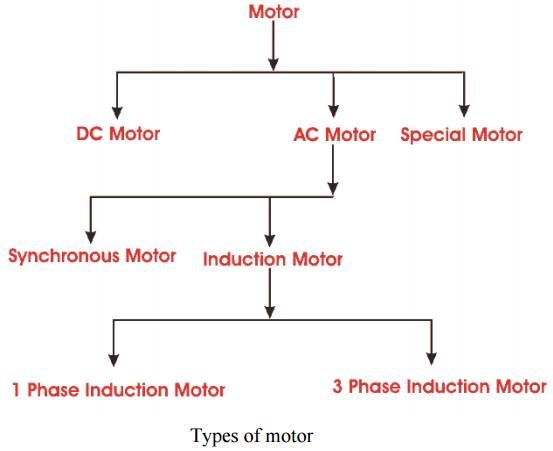

Types of Electric Motors

Mainly there are two types of motors AC or DC motors which are further subdivided in different classes. In a DC Motor direct current electricity is used to convert it in to motion, DC motors can run directly on rechargeable batteries making them more portable to use at flexible locations and purposes. Two main types of DC motors are Brush DC & Brushless DC motor. Brush DC motor uses and internal powers supply with stationary magnets, while Brushless DC motors use for rotation the permanent magnets. In summary we can classify electric motors as under:

- AC Motors

- DC Motors

- Synchronous Motors

- 3 Phase Induction Motor

- Single Phase Induction Motor

- Special Motor

Classification of DC Motor

- Permanent magnet DC motor

- Separately excited DC motor

- Series field wound DC motor

- Shunt field wound DC motor

- Compound motor

Stepper DC Motor:

A stepper motor is a brushless DC motor that drives full rotation into multiple steps. The motor’s position can move and hold at one of these steps without any feedback sensor. Stepper motors are used in Floppy disk drives, plotters, CD ROMs, scanners and many other appliances.

Servo Motors:

Servo motors are used in servomechanisms. A Servomechanism is an automatic device that uses error sensing to improve machine performance Servo Motors are capable of producing 8,000 to 70,000 RPMs for high torque requirements in special design applications

Types of losses in induction electric motors

Now let us talk a little bit about the losses which are occurring in electric motors due to many reasons. There are electrical losses happening due to heat produced in the stator and rotor winding which are also called copper losses in a motor. Other losses include magnetic loss in the iron due to hysteresis and eddy current, mechanical loss due to friction in the bearing and ventilation system and stray load losses. Mechanical losses vary slightly with load and speed and this variation is considered to be negligible

What is Electric Motor Efficiency?

The efficiency of any electric motor can be computed by measuring the ratio between the shaft power out put to the electrical input. i.e.

Ƞ = P out/P in

Ƞm = (Pout )(746)/Pin

when Pout is in hP (horse power)

If we talk about the Energy Efficient motors these are able to run at 2 to 8 percentage more efficiency than the standard motors. Means they are able to give same out put by consuming lesser amount of power. High efficiency electric motors are always costly because these are produced by using more copper in the winding leading to reduced fan loss. Other features of efficient electric motor include Higher quality thinner steel lamination, optimal air gap between rotor and stator and greater length high quality aluminum used in the rotor frame.

Some Tips for Efficient Electric Motor Operation

- Properly lubricate moving parts

- Keep motor couplings properly aligned

- Properly align tension belts while installing the motor

- Keep bearings clean and lubricated

- Check proper supply voltage

Discover more from Electrical Engineering 123

Subscribe to get the latest posts sent to your email.

It’s interesting to read about some of different efficiency losses in electric motors. It makes sense that there are mechanical losses, caused by bearings and heat, while there are also magnetic and electrical losses. This is something to keep in mind when I’m looking at various motors because considering the losses and how they might grow over time would be helpful to ensure I get a motor powerful enough to handle the application for a long time.