A contactor is an electrically controlled switch used for switching an electrical power circuit , similar to a relay except with higher current ratings. Contactor is in fact an electromechanical switch.

Low-voltage Contactor is an electrically controlled switch used for switching an electrical power circuit, similar to a relay except with higher current ratings. A contactor is controlled by a circuit which has a much lower power level than the switched circuit.

A contactor is a relay that is used for switching power. They usually handle very heavy loads like an electric motor, lighting and heating equipment’s etc.

Though their output is used for switching very high loads, they are controlled by a circuit with very less power. According to the loads they handle, they vary in sizes from a small device to as huge as a yard .

Unlike circuit breakers contactors are used for switching purposes only, they do not interrupt a short-circuit current like a circuit breaker.

Contactors have ratings ranging from a breaking current of a few amperes and 24 DC volts to thousands of amperes with many kilo volts.

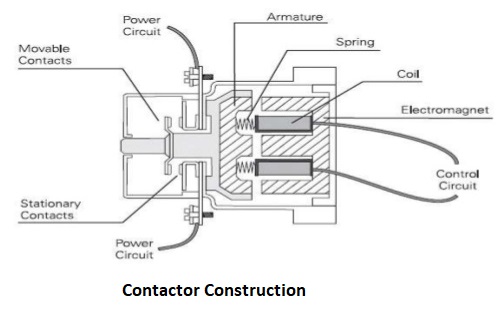

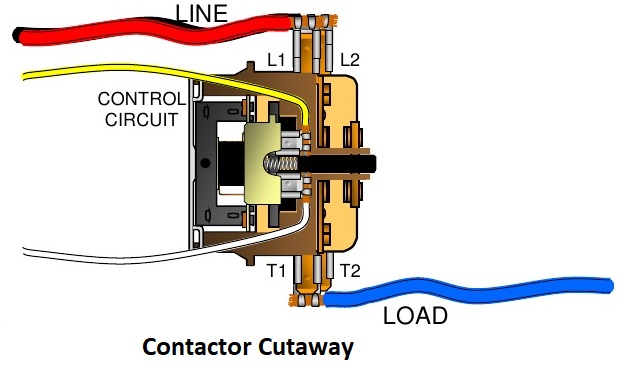

Construction of Contactor

Below diagrams explain the construction of contactor.

Components of contactor

- Movable contacts

- Stationary contacts

- Armature

- Spring

- Electromagnet

- Power circuit

- Control circuit

- Coil

Mainly there are two types of coils in a contactor i.e. AC coil and DC coil. In AC coil the options available are for 110, 240 and 415 volt while in DC coil options are for 12 and 24 volt.

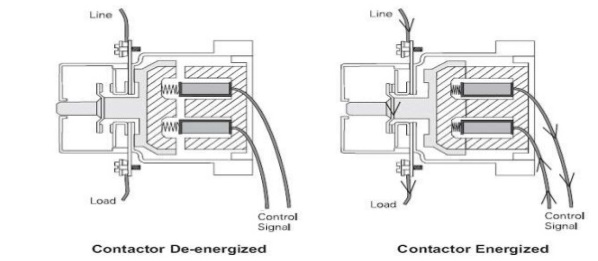

Operating Principle of Contactor

Mechanical Life of contactor is over when

- In the E shaped Magnets

- Air gap reduces to Zero

- The contactor fails to drop out

- Shading rings breaks

- Damage to mechanical parts

- Damage to Springs

Electrical Life is over when the contact Silver material wears away.

Advantages and Disadvantages of Contactors

Advantages of contactors include:

- Protection

- Simple Operation

- High-load capacity

- Low power consumption

- Fast switching

Disadvantages of contactor include absence of overload protection and malfunction due to excessive use of contacts.

Application of Contactors

Lighting Control Contactors are often used to provide central control of large lighting installations, such as an office building or retail building.

To reduce power consumption in the contactor coils, latching contactors are used, which have two operating coils. One coil, momentarily energized, closes the power circuit contacts, which are then mechanically held closed; the second coil opens the contactor.

Magnetic Starter: A magnetic starter is a device designed to provide power to electric motors. It includes a contactor as an essential component, while also providing power cut-off, under-voltage, and overload protection.

Common Contactor Complaints and Field Failures

- Burned contacts

- Burned coils

- Open coils

- Stripped Screws/terminal threads or loose connection

- Noise

- Loose/misaligned springs

Field Failures Causes of Contactor

Failure Causes of Burned Contacts

- Mismatch between device current/voltage ratings and load

- Low voltage at the coil causing chattering and excessive arcing of contacts∙ Bad riveting of contacts to carrier

- Environmental causes (temperature, humidity, minerals)

Severity of Failure

- Arcing may propagate and create further damage and fire

- Costly to replace in field installed equipment

- Critical systems would require backup or redundant system

Failure Causes of Burned Coils

- Low voltage to the coil – below contactor pickup volts∙ High voltage to the coil – exceeding coil rating

- Many nicked wire turns – insulation removed causing shorts

- Environmental causes

Severity of Failure

- Burned coils release toxic gases and may potentially contribute to a fire

- Costly to replace in field installed equipment

- Critical systems would require backup or redundant system

Causes of Open Coils

- Reliability issue with magnet wire termination – bad solder or crimp joint

- Voltage surge causing terminations to break

- Coil opens at another location such as outer winding due to previous damage

- Environmental causes

Severity of Failure

- Failure to operate may be intermittent depending on nature of break

- Open coils are not normally a safety problem for the equipment

- Costly to replace in field installed equipment

- Critical systems would require backup or redundant system

Causes of Stripped Screws

- Customer Connections

- Threads not per specification

- Screws not started correctly

- Excessive tightening torque

- Environmental causes (corrosion)

Severity of Failure

- Customer connection may not be secure

- Potential fire hazard

- Costly to replace in field installed equipment

Precautions for Reliability of Contactor

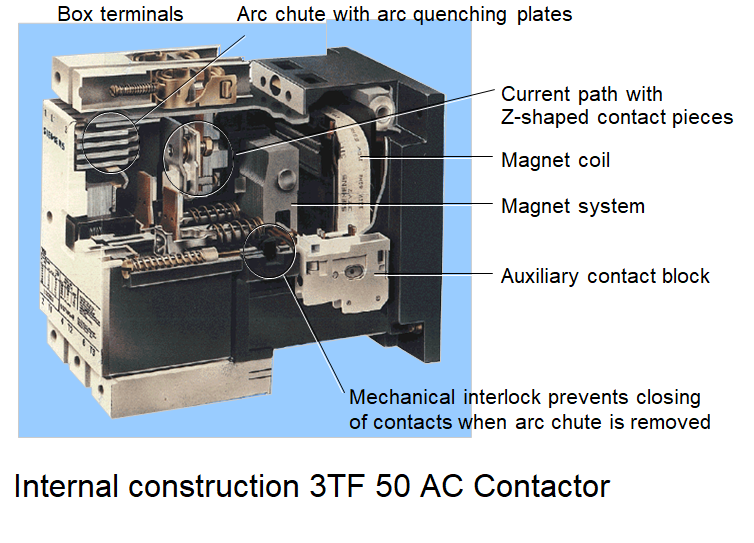

- Do not operate contactor without Arc Chamber

- Do not use repaired contacts or coils or Arc chambers

- Do not file or rub the surface of contacts with abrasives

- Clean contacts with CRC 2-26

- Replace contact in pairs

- Proper connection of the cable/bus bar at the contactor terminal

- Please Ensure correct tightening torque

- Use only Genuine spare parts

- Connection with Lugs / Busbars to Busbars Should be

- Wire brushed

- Wiped with clean cloth chambers

- Apply Dowells compound

- Tighten with requisite tightening torque

- Use bimetal washers when using 2 different metals

- The mV drop across a joint should be less than 4mW

Summary of The Article

- Contactor is an electro-mechanical switching device which is remotely operated.

- A contactor should be capable of making, carrying and breaking currents under normal conditions and during operating overload conditions.

- It is placed nearest to the load center e.g. for Switching motors, lights, capacitors,heaters,furnaces etc

- They have high service reliability in terms of high mechanical and electrical life is demanded.

- A contactor consists of 3 subsystems

- Electromagnet system

- Contact and Arc quenching system

- Housing