To better understand the servo motor let us first see what is the meaning of term “servo”. The term servo is applicable for any system that uses a feedback mechanism in order to control the required situation. The feedback can be in the form of signals from sensors or limit switches or number of revolutions, rpm etc.

So we can say that servo is a small device that has an output shaft which is adjustable to specific angular positions by sending the servo a coded signal.

A servo motor can be a DC motor, AC motor, or brushless DC motor that is combined with a position sensor or referred as a digital encoder. Precise servo control mechanism provides high degree of confidence for the purposes where high degree of accuracy is desirable.

What is Servo Motor?

Servo motor is defined as an automatic device that uses an error-correction routine to correct its motion. A servomotor is a rotary actuator or linear actuator that allows for precise control of angular or linear position, velocity and acceleration. It consists of a suitable motor coupled to a sensor for position feedback.

There are three types of servomotor i.e. positional rotation servo, continuous rotation servo and linear servo.

Construction & Components of Servo Motor

Servomotor consists of following components:

- Motor

- Gears

- Shaft / servo drive

- Position Sensor

- Control Circuit / servo control

- Power Supply

- Control Circuit/Wiring

A servo motor consists of three major parts i.e. motor, control board or servo controller, and potentio-meter (variable resistor) connected to the output shaft or servo motor drive. The motor utilizes a set of gears to rotate the potentiometer and the output shaft at the same time. The potentiometer, which controls the angle of the servo motor, allows the control circuitry to monitor the current angle or position of the servomotor.

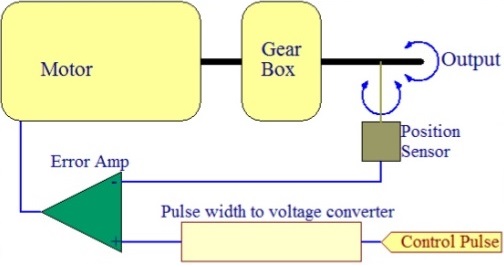

Servo motor controller / servo control is a circuit that is used to control the position of a servo motor. It is also called as a servo motor driver. A servo motor controller consists of a controller, the servo motor and the power supply unit.

How Servomotor Works?

Servo motor uses a series of gears in order to turns the output shaft and the potentiometer simultaneously. Signals from potentiometer goes to servo control circuit and when the control circuit detects that the position is correct, it stops the servo motor.

On the other hand if the control circuit finds the angle or position is not correct, it will turn the servo motor the correct direction until the angle is correct or the required position is detected.

Normally a servo motor is used to control an angular motion of between 0 and 180 degrees. It is not mechanically capable (unless modified) of turning any farther due to the mechanical stop build on to the main output gear.

Servo Motor Working Principle of Operation

Servomotor is controlled by sending an electrical pulse of variable width, or pulse width modulation (PWM), through the control wire. There is a minimum pulse, a maximum pulse, and a repetition rate. A servo motor can usually only turn 90 degrees in either direction for a total of 180 degree movement.

The motor’s neutral position is defined as the position where the servo has the same amount of potential rotation in the both the clockwise or counter-clockwise direction.

Torque Rating of servo motor:

The maximum amount of force the servo can exert is called the torque rating of the servo. Servos will not hold their position forever though; the position pulse must be repeated to instruct the servo to stay in position.

Characteristics of Servo Motor

Power Supply Voltage and Current: The common RC servo motors powered from supplies in the range of 4 – 6 V and 100 mA – 2 A .

Operating Speed: Common servos have operating speeds in the range of 0.05 to 0.2 s/60 degree.

Torque: Typical values of torques of servo motors are in the range of 0.5 to 10 kg/cm.

Control Pulse: Two main types of control pulses used in RC applications i.e. center position in 1-2 ms and 1.25- 1.75 ms.

Resolution: Typical servo motors have resolutions in the range from 1 degree to 10 degree.

Size and Weight: Typical RC servo motors have a weight range between 15 and 200g.

Advantages of Servomotor

If a heavy load is placed on the motor, the driver will increase the current to the motor coil as it attempts to rotate the motor. Basically, there is no out-of-step condition. Another advantage is that high-speed operation is possible.

Disadvantages of Servomotor

Since the servomotor tries to rotate according to the command pulses, but lags behind, it is not suitable for precision control of rotation. Its cost is higher. Another drawback is that when stopped, the motor’s rotor continues to move back and forth one pulse.

Servo motor applications

At industrial level servomotor is useful in machine tools, packaging, factory automation, material handling, printing converting, assembly lines etc.

Servo system is also useful in precision monitoring like robotics, CNC machinery and other automated manufacturing.

Servomotor is used by aerospace industry to maintain hydraulic fluid in their hydraulic systems.

Useful in many radio controlled toys and electronic devices such as DVDs or Blue ray disc players to extend or replay the disc trays.

Servo motors are also being used in automobiles to maintain the speed of vehicles

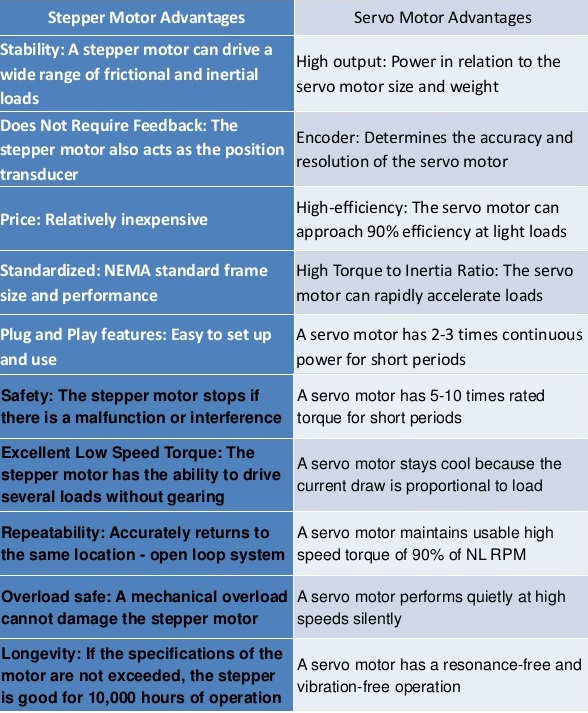

Comparison of Servo motor and stepper motor

Discover more from Electrical Engineering 123

Subscribe to get the latest posts sent to your email.