The purpose of this article is to define the sequence and methodology for the installation of electrical cable trays, cable trunking, cable raceways and boxes, junction and pull boxes.

The method gives details of how the work will be carried out and what health and safety issues and controls that are involved. The content of this electrical method statement also reflects the findings of the relevant risk assessment.

Below is list of necessary plant and equipment for this electrical work method.

- Cutting tools I machine

- Drilling machine

- Screw driver

- Spanner

- Grinding machine

- Measuring tape

- Working Platforms: Scaffolding as required within the specific work area.

- Full PPE as per risk assessment and site safety plan and procedures

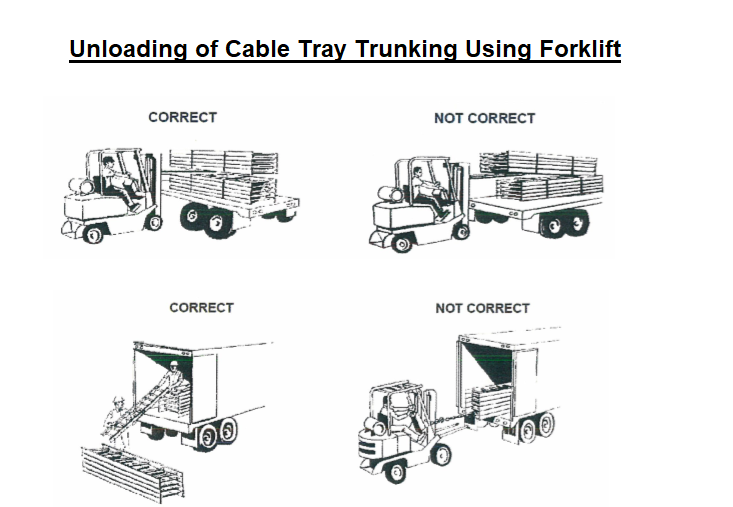

Cable tray and related materials will be shipped via an enclosed van, trailer, or flatbed trailer. The shipments will be hand unloaded or by using forklift. If the provision for unloading of materials is crane the safety lifting plan is mandatory for the work activity.

Below is list of necessary plant and equipment for this electrical work method.

Cutting tools I machine

Drilling machine

Screw driver

Spanner

Grinding machine

Measuring tape

Working Platforms: Scaffolding as required within the specific work area.

Cable Tray, trunking and ladder will be properly supported and stacked in a flat surface.

Tray, trunking and ladder will be stored in a covered area to prevent water or other foreign materials from staining or adhering

Cable Tray, trunking and ladder will be protected from sunlight and moisture by covering them using tarpaulin.

Painted cable tray and trunking will be protected and stored indoors if possible.

Cable tray will be protected from scratching and marring of finish.

Accessories will be stored to prevent loss.

Containment materials will be stored away from high traffic areas.

All the cable containment materials will be stacked by width and type.

Containment materials and accessories will be sorted as per manufacturer recommendations.

Cable Tray Pre Installation Requirements

A pre start meeting prior to the commencement of the cable containment installation works will take place with the Site Engineer, H&S Officer, QC Engineer, Supervisor/Foreman in charge to address the following:

Ensure that the area has been surveyed as per approved drawings

Check that the installation area is clean from debris and foreign matter

Ensure that material is as per approved Material Submittal and Contract Specifications

Make sure that adequate number of tradesmen and proper tools are present.

Ensure that latest approved shop drawings for the installation are present, and all personnel are working to the same drawing.

Verify that area is safe to carry out the work. The Supervisor must ensure that the workers working at height are trained and all safety precautions are taken according to HSE requirements and the JSEA.

Before any permanent work will proceed, pre-inspection of all materials, tools and access for installation to be carried out.

Method of Installation of Cable Tray, Trunking and Ladders

Cable Tray, trunking and ladder will be installed according to approved shop drawings, checklist and as per contract specifications.

Installation will be carried out by skilled and suitably experienced electricians under supervision of highly competent site supervisors and engineers to be ensured the correctness and quality of installation.

Establish the route on slab soffit and walls, mark with chalk liner. Ensure that the rout conform to the latest coordinated drawing.

Mark the location of supports for vertical and horizontal cable containment installations.

Install the threaded rod and Unistrut channels as per the typical details shown in the approved drawing.

Installation will be coordinated to other services to avoid clashes and conflicts.

Burrs and sharp edges will be removed from cable trays and cable trunking.

Cable Tray, trunking and ladder supports will be fasten to building structure and seismic restraints will be installed where required.

Cable Tray, trunking and ladder supports will be install directly to slab surface and using other services supports will not be allowed .

Installation of cable trays, trunking and ladders are properly fixed to its supports.

Spring knot will be used to make sure cable tray will be firm and not be displaced.

Space connector and set gaps according to applicable standard.

Make cable tray, trunking and ladder connections using standard fittings.

Cable tray and trunking will be installed with enough space to permit access for installing cables.

Containment trays will be properly aligned and securely fixed at intervals not exceeding 1.2m on centre in straight runs.

Trunking will be fixed and supported at 2m interval.

Trunking angles, bends, and offsets will be fixed with additional fixings at distance not exceeding 150 mm on each side of the fitting.

Where trunking which is installed in such a position that the cables would fall out when the cover is removed, shall be fitted with cable/ wire retaining bars or other suitable devices of non-hygroscopic insulating material at to prevent the cables from falling out.

All un-used holes in cable containment to be fix with grommet.

When cable tray and trunking are used or installed in direct sun exposure, it will be cover to protect from heat radiation.

Direct mounting for the cable trays, trunking to the ground should be avoided, 50 mm clearance or spacing to be maintain over the floor.

Cable tray cutting will be made using a hand held hack saw or jigsaw machine. It is important to get a square cut to ensure a good splice connection. After cutting, smooth the cut edges to remove any burrs and painting with rust proofing agent.

There will be no site fabrication for all fittings that will be used. All fittings will be from approved manufacturer.

Trunking connections to conduits, multiple boxes, switchgear and distribution boards will be made with flanged units.

Steel flush and steel under floor trunking will be installed directly in the concrete floor, positioned and secured before the slab is poured.

Flush floor trunking lids will be perfectly flush with adjacent concrete floor, to allow covering by floor finishes.

Cable ladder will be installed wherever applicable like as horizontal and vertical containment for cables going to HV and LV panels or as illustrated in approved shop drawings.

Paint retouch up will be provided to all cut ends as required.

Prior to cable pulling, trays and trunking will be ensure to be free from dust, dirt or any construction debris.

After the cable pulling, end cap will be provided for cable trays and cable trunks as well as trunking cover.

Expansion fittings will be provided for expansion joint connection.

Earth bonding jumper will be provided to cable trays and trunking joints.

Label indicating the system to be provided for proper identification as per contract specifications.

After installation, Inspection Request will be raised to the consultant to ensure high accuracy and quality of works.

Checklist for Quality Control of Containment Installation

- Approved material used (MIR Approval)

- Shop drawing is approved.

- Installed hanger and supports are inspected and approved.

- Distances between support s are as per approved drawing.

- Installed cable tray, trunking or ladder are levelled and straight.

- Spring knot is used to connect cable tray or trunking to channel.

- Approved and correct fittings are used.

- Bonding jumper is installed.

- Expansion fittings are used as required.

- Painting is applied to cut ends.

- Tagging/labelling is provided.

- Installed containments are free of damages and scratches.

Discover more from Electrical Engineering 123

Subscribe to get the latest posts sent to your email.