The lighting system installation work shall cover the supply and installation of lighting system equipment such as Main lighting distribution boards (MLDBs), lighting distribution boards (LDBs), receptacles, light control switches, ceiling fans, lighting wires, conduits, junction boxes, lighting poles, towers, etc.

Lighting company shall carry out the installation of various lighting equipment as indicated in the approved drawings. The work shall include unloading, storing, unpacking, fixing of all equipment, routing and laying of conduits/cables, wiring, termination, testing and commissioning of all the equipment of lighting system.

The supply of all mounting accessories, earthing wires and incidental hardware and consumable like fixing saddles, spacer plates, junction boxes and conduits required for the fitting fixing/suspension points, joint boxes and connectors, jointing, ferrules, all fixing brackets, screws and studs, shall be deemed to be included as part of installation work.

Mounting accessories like saddles, spacer plates, joint boxes, junction boxes and fixing hardware shall be of galvanised mild steel/black enameled steel.

Holes in wall made shall necessarily be patched-up in a good and approved manner, using the same kind of masonry as in the uncut surfaces. Provide touch-up painting on lighting panels/boards if the same is damaged during installation handling.

Light Fixtures

Fixtures shall be firmly supported from the structures. Support clamps etc., may be bolted or welded to the existing steel works or metal inserts. In case of concrete structures where metal inserts are not available, fixtures having a weight up to 2.5 kg shall be supported by minimum two numbers nylon sleeve anchor of approved made.

Flameproof or other heavier fixtures shall be supported by using metallic anchor fasteners of approved size. All supports shall be thoroughly cleaned and painted in an appropriate color to suit the fixture.

In case of false ceiling employing minimum tee grid system, fixtures shall be supported from true ceiling. Exact locations of fixtures shall be finalized in consultation with air-conditioning contractor and as indicated on Architectural drawings. Wiring above false ceilings shall not left loose and shall be supported along the structures/ceiling. Wiring above false ceiling shall be on surface and below false ceiling it shall be concealed.

To facilitate easy maintenance “Looping back system” of wiring shall be followed throughout. Accordingly supply tapping and other interconnections are made only at fixture connector blocks or at switchboards. Intermediate junction boxes shall be used for wire pulling as inspection boxes.

Conduit Installation for Lighting System

Surface or concealed conduit system of wiring shall be adopted. Indoor building wiring shall be concealed conduit system Suitable pull boxes or inspection type fittings will be used to facilitate drawing of wires.

Only threaded type conduit fittings shall be used. Pin Grip type or clamp type fittings are not acceptable. Conduit ends shall be free from sharp edges or burrs. The ends of all conduits shall be reamed and neatly bushed with Bakelite bushings.

All screwed connection shall ensure that at least five threads are engaged and the electrical continuity of conduit is maintained. Threading of conduit shall be done to close tolerance.

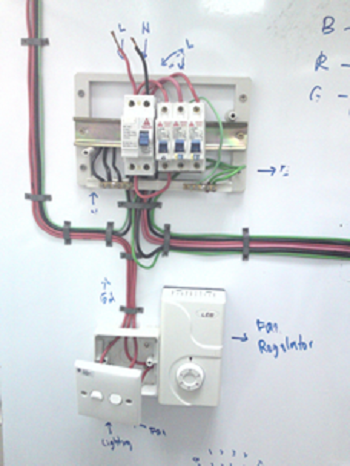

An ELCB box in residential and fan regulator plus socket for lighting and fan straight from the ELCB

In order to minimize condensation of sweating inside the conduit system, all outlets shall be properly drained and ventilated in such a manner so as to prevent entry of insects.

The outer surface of the conduit pipes, including all accessories forming part of the conduit system, shall be adequately protected against rust, particularly when such system is exposed to weather.

In all cases, bare threaded portion of conduit pipe shall not be allowed unless such bare threaded portion is treated with anticorrosive preservative or covered with approved plastic compound. Conduit connection to outlet boxes shall be by means of screwed hubs or check nuts on either side.

Conduit pipes shall be fixed by 16 gauge G.I. Saddles on 25×6 mm G. I. Saddles bars in an approved manner at intervals of not more than 250mm. Saddles shall be fixed on either side of couplers, bends or similar fittings, at a distance of 300 mm from the centre of such fittings.

The cost of saddle bore, saddles, clamps etc. shall be deemed to have been included in the pricing for installation of conduits.

Wherever surface conduit is specified, Inspection bends, Elbows or Tees shall not be used unless shown on the drawings or specifically approved. Bends shall be avoided as far as possible. Joints and use of conduit nipples shall be kept to a minimum.

Where concealed wiring is to be adopted, conduit or capping casing shall be laid with the civil works in such a way.

Vertical conduit runs shall be made either through columns or encases prepared in the walls.

Contractor shall fill these encases or any other openings made by him after completing the work and neatly finish the surface.

During installation, care shall be taken to see that adequate covers are provided to prevent rusting of conduits.

If required, conduit runs may be concealed in the floor for low level receptacles and exhaust fans.

For as built conduit paths contractor shall submit layout drawing.

Wiring for exhaust fans shall be terminated in ceiling/roses/receptacles and the connection from ceiling/rose/receptacle to the exhaust fan shall be by means of a flexible cord equivalent in size to the main run of wires.

Street Lighting & General Plant Lighting

Lighting poles shall be installed as per relevant approved drawing. Fixture wire from marshalling box up to fixture shall be 2.5 mm2, PVC insulated copper Conductor. Main feeder up to the marshalling box shall be as per the respective drawings.

Each pole shall be grounded by connecting it to the plant ground grid with suitable size of earth conductor.

Outdoor lighting distribution boards LDBs for street lighting/area lighting shall have ON/OFF operation through real time based timer control in addition to manual control.

In this case incomer to LDB shall have suitably rated contactor in addition to MCCB and same shall be controlled by timer contacts. The outgoing feeders of indoor LDB used for street lighting/area lighting shall have timer controlled contactors in addition to MCB

Discover more from Electrical Engineering 123

Subscribe to get the latest posts sent to your email.